PRODUCTS

Optical Hardened Film

Anti-Scratch and Explosion-Proof Protective Film

2.5D/3D Glass Protective Film

Photoelectric Fingerprint Unlock Protection Film

Anti-Glare Film/Anti-Reflection Protective Film

Acrylic Protective Film

Silicone Protective Film

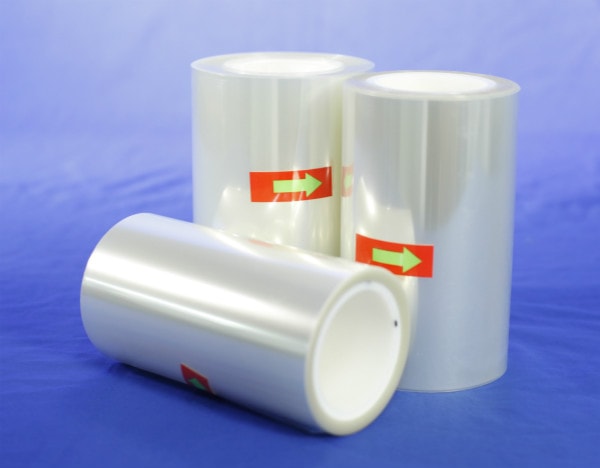

Single Layer Protective Film

PU Protective Film

CPP protective film

Flame-Resistant PET tape

Heat High Temperature Resistant Adhesive Tape

AB Tape

Double Sided Coated Tape

Polyimide Tape (Kapton Tape)

Conductive Tape/Shielding Tape

Masking Tape

Kraft Paper Tape